Product/Service Description

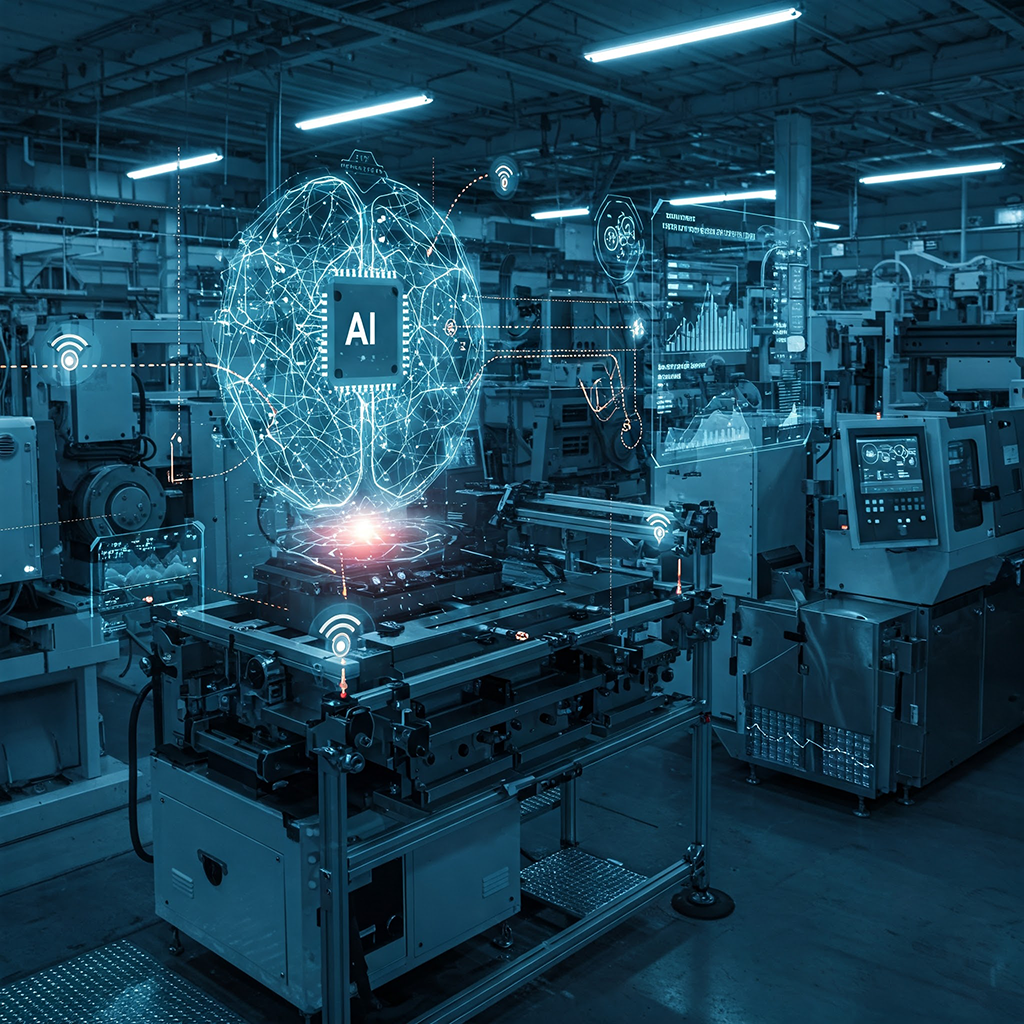

This solution integrates Artificial Intelligence (AI) with the Internet of Things (IoT) to provide advanced capabilities for industrial equipment, including remote monitoring, health prediction, anomaly detection, and diagnostic services.

The primary objectives are to maximize equipment uptime, reduce unforeseen downtime, optimize maintenance schedules, cut maintenance costs, and extend the operational lifespan of machinery. The solution can span the entire lifecycle from developing custom sensor hardware and data acquisition/transmission systems to establishing cloud-based management platforms and deploying sophisticated AI models for "predictive maintenance." By analyzing diverse operational parameters from equipment (like vibration, temperature, and audio signatures), AI algorithms can predict potential failures with high accuracy and issue early warnings. This enables a shift from reactive to proactive, predictive maintenance strategies.

The value of AIoT lies in its ability to convert vast streams of sensor data into actionable intelligence for maintenance decisions, relying on high-quality historical data and advanced machine learning techniques such as time-series analysis and anomaly detection models.

The primary objectives are to maximize equipment uptime, reduce unforeseen downtime, optimize maintenance schedules, cut maintenance costs, and extend the operational lifespan of machinery. The solution can span the entire lifecycle from developing custom sensor hardware and data acquisition/transmission systems to establishing cloud-based management platforms and deploying sophisticated AI models for "predictive maintenance." By analyzing diverse operational parameters from equipment (like vibration, temperature, and audio signatures), AI algorithms can predict potential failures with high accuracy and issue early warnings. This enables a shift from reactive to proactive, predictive maintenance strategies.

The value of AIoT lies in its ability to convert vast streams of sensor data into actionable intelligence for maintenance decisions, relying on high-quality historical data and advanced machine learning techniques such as time-series analysis and anomaly detection models.