Product/Service Description

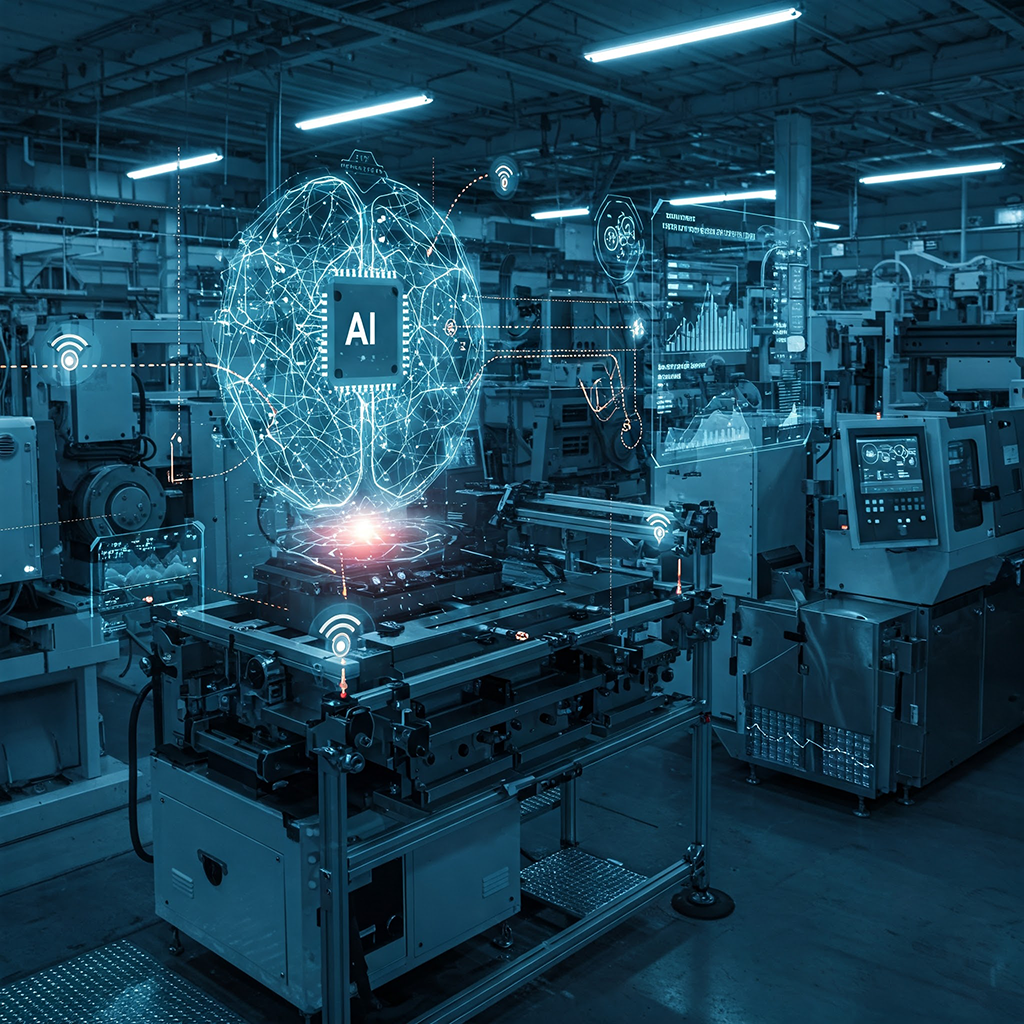

With the arrival of the Industry 4.0 era, smart logistics and manufacturing are gradually becoming the primary paths for global businesses to enhance efficiency and competitiveness. In this trend, Allkym has emerged as a leader in this field, leveraging its cutting-edge artificial intelligence and collaborative robotic arm technology.

Core advantages of automated picking systems:

Ultimate Efficiency: Utilizing advanced AI technology for the swift identification and localization of goods.

Precision Operations: Collaborative robotic arms perform quick and accurate picking tasks 24/7. Dual Assurance of Cost and Safety: Substantially reducing labor costs while ensuring workplace safety.

Highlights of intelligent manufacturing technology: Allkym's unique technology enables precise grasping of objects of various shapes and materials, adapting to irregular or soft items such as fruit sorting. Through image recognition and robotic arm technology, Allkym has successfully addressed challenges related to escalating labor costs and manpower shortages.

Market footprint: Allkym has collaborated on research with relevant European enterprises to explore more efficient solutions. Traditional logistics methods hinge on the structure and shape of items, yet Allkym's technological approach offers heightened flexibility, especially suitable for small, irregular, or soft items.

Conclusion: As a frontrunner in intelligent manufacturing and logistics, Allkym not only delivers the dual benefits of efficiency and cost savings to businesses but also ensures the safety and dependability of operational workflows.

Core advantages of automated picking systems:

Ultimate Efficiency: Utilizing advanced AI technology for the swift identification and localization of goods.

Precision Operations: Collaborative robotic arms perform quick and accurate picking tasks 24/7. Dual Assurance of Cost and Safety: Substantially reducing labor costs while ensuring workplace safety.

Highlights of intelligent manufacturing technology: Allkym's unique technology enables precise grasping of objects of various shapes and materials, adapting to irregular or soft items such as fruit sorting. Through image recognition and robotic arm technology, Allkym has successfully addressed challenges related to escalating labor costs and manpower shortages.

Market footprint: Allkym has collaborated on research with relevant European enterprises to explore more efficient solutions. Traditional logistics methods hinge on the structure and shape of items, yet Allkym's technological approach offers heightened flexibility, especially suitable for small, irregular, or soft items.

Conclusion: As a frontrunner in intelligent manufacturing and logistics, Allkym not only delivers the dual benefits of efficiency and cost savings to businesses but also ensures the safety and dependability of operational workflows.