Product/Service Description

¡iTraditional institution¡j

Most of the spiral water chillers are operated in four stages (25%, 50%, 75%, 100%) to perform unloading operation in sections, so that when the environmental load is not high, it can be operated at a relatively low current.

However, its The speed of the compressor is still running at full speed (60HZ), which is the energy saving base point that the frequency converter can import.

The frequency conversion energy-saving module of Shangjin can greatly change the speed of the compressor. At this time, the reduction of energy consumption will be much greater than that of the four-stage unloading. Therefore, the current new water chiller planning is based on the frequency conversion model.

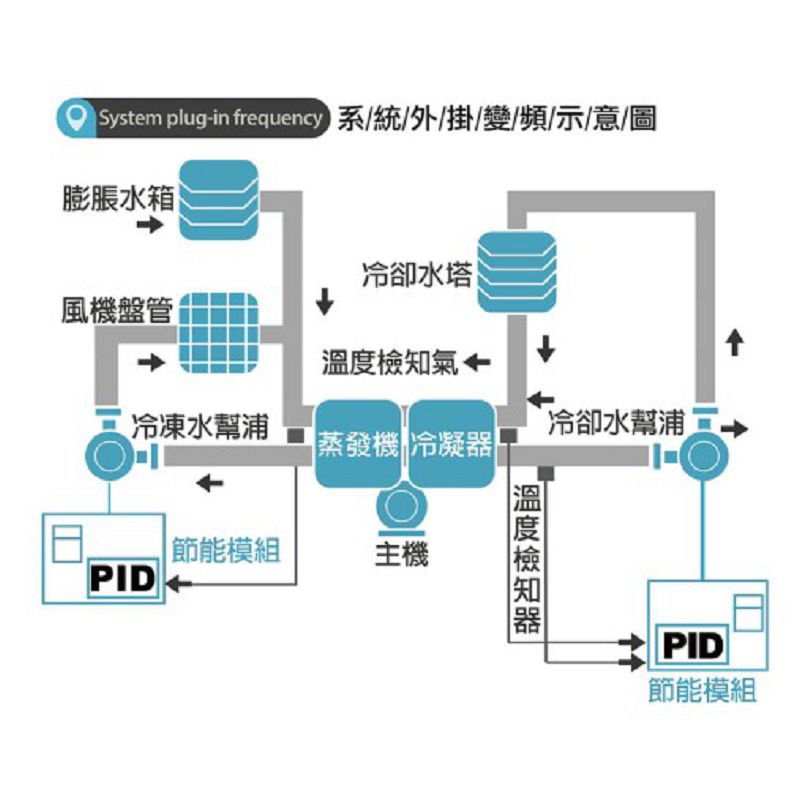

¡iEnergy Transformation of Air Conditioning System¡j

Control of cooling water circulation system: Frequency conversion control is realized by detecting the temperature difference between inlet and return water, which can achieve the purpose of energy saving and carbon reduction.

Control of the chilled water circulation system: The frequency conversion control can be achieved through the return water temperature to achieve the purpose of energy saving and carbon reduction.

¡iOverload Design¡j

In all new projects, the design of the air-conditioning system is based on the peak load as the main design basis, and the design of the load has been grasped upwards.

However, the peak load only accounts for 5~10% of the total running time. It can be said that most of them are running at part of the load, so there is a lot of energy saving space. Energy can be saved by the inverter.

Most of the spiral water chillers are operated in four stages (25%, 50%, 75%, 100%) to perform unloading operation in sections, so that when the environmental load is not high, it can be operated at a relatively low current.

However, its The speed of the compressor is still running at full speed (60HZ), which is the energy saving base point that the frequency converter can import.

The frequency conversion energy-saving module of Shangjin can greatly change the speed of the compressor. At this time, the reduction of energy consumption will be much greater than that of the four-stage unloading. Therefore, the current new water chiller planning is based on the frequency conversion model.

¡iEnergy Transformation of Air Conditioning System¡j

Control of cooling water circulation system: Frequency conversion control is realized by detecting the temperature difference between inlet and return water, which can achieve the purpose of energy saving and carbon reduction.

Control of the chilled water circulation system: The frequency conversion control can be achieved through the return water temperature to achieve the purpose of energy saving and carbon reduction.

¡iOverload Design¡j

In all new projects, the design of the air-conditioning system is based on the peak load as the main design basis, and the design of the load has been grasped upwards.

However, the peak load only accounts for 5~10% of the total running time. It can be said that most of them are running at part of the load, so there is a lot of energy saving space. Energy can be saved by the inverter.